By breaking down the limitations of traditional filament-based 3D printing, we aim to drive the future with accessible and sustainable 3D printing.

Microplastic Waste Formation

Low Recycling Rate

High Global Waste

Inefficient Energy Consumption

High Carbon Emission

High Carbon Footprint

These topics coincide with the innovative solutions we develop, focusing on environmental sustainability and efficient use of resources. As Nolega, we are proud to contribute to these global goals.

Plastic raw materials begin their lives as plastic granule particles.

80% of today's 3D printers require plastic raw materials in the form of thread called filament.

High energy consumption and carbon emissions are required to turn plastics from granule into filament.

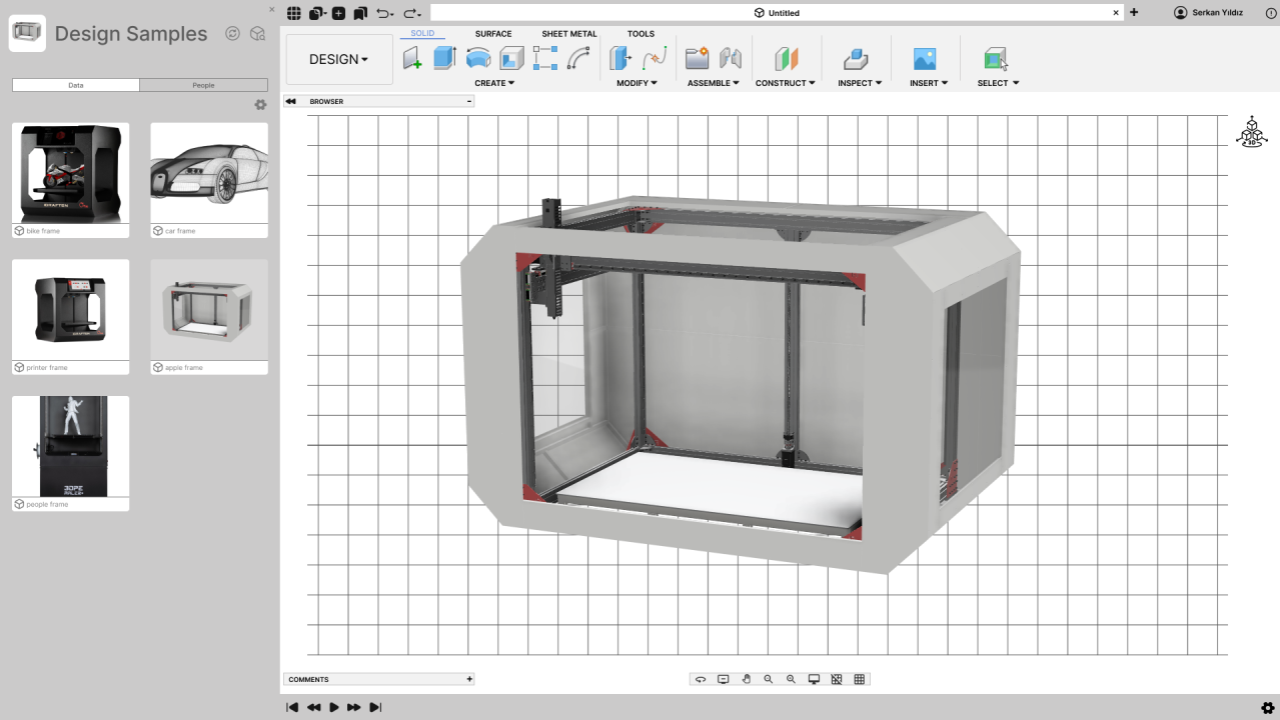

Nolega, produces solutions to sustainability problems in the industry by developing pellet extruders that enable 3D printer users to print plastics directly in granular form, as well as various products for use in recycling processes.

With our constantly expanding product family, we touch every stage of production, providing comprehensive solutions.

Simplify your work with Nolega's 100% compatible custom software solution. Use our products more efficiently and speed up your work.

We are a team of engineers, designers, and business professionals who are passionate about 3D printing and its potential to change the world. We are dedicated to creating innovative solutions that push the boundaries of what is possible with Additive Manufacturing.